Pumps

Manufacturers: Sam turbo India, CW Hydro INC, IL Sung pump etc.

Axial Split Casing Pumps

Operating Range:

| Capacity | upto 4000 m3/hr |

| Head | upto 150m |

| Temperature | upto 220° C |

| Pressure | upto 40 bar |

Design: Horizontal, axially split single stage, inline design volute casing pumps with double suction, radial impeller according to API – 610 7th edition.

Application: This process and transfer pump has been developed for the most exacting conditions and can be used for a multitude of operations such as for pumping crude oil, oil and liquid hydrocarbons, furthermore for pumping cooling water, hot water, river water, brackish water as well as sea water, and also acids and alkalis. This type can also be used for loading in tank farms and as fire water pumps in fire fighting systems.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C, and material combination as per API – 610.

Chemical Process Pumps

Operating Range:

| Delivary Size | DN 32 to 200 mm |

| Capacity | upto 750 m3/hr |

| Head | upto 150m |

| Temperature | upto 150 C |

| Pressure | upto 22 bar |

Design: Horizontal, radial split, volute casing pumps according to DIN 24256 with closed impeller, end suction, top centre line discharge. Back pull out design enables to remove the rotor without disturbing the pipelines. If a spacer coupling is used, the motor does not have to be removed from the base plate. Only four bearing beds cover the entire 32 models. This means that the shafts, sleeves, bearings, and bearing beds are identical in and interchangeable for a large number of pump sizes.

Application:

- Chemical, Petrochemical, refineries, paper, and sugar industries.

- Suitable for hydrocarbons, acids, aggressive products, inorganic and organic chemicals

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

Chemical Process Pumps

Operating Range:

| Delivary Size | DN 25 to 200 mm |

| Capacity | upto 700 m3/hr |

| Head | upto 180m |

| Temperature | upto 260° C |

| Pressure | upto 26 bar |

Design: Horizontal, radial split, volute casing pumps according to ANSI B73-1 specifications with open impeller, end suction, top centre line discharge. Simple external axial adjustment for impeller wear. Back pull out design enables to remove the rotor without disturbing the pipelines. If a spacer coupling is used, the motor does not have to be removed from the base plate. Only four bearing beds cover the entire 32 models. This means that the shafts, sleeves, bearings, and bearing beds are identical in and interchangeable for a large number of pump sizes.

Application:

- For handling all chemical process requirements like acids, alkalis, corrosive slurries, hydrocarbons etc.

- Suitable for all liquids with/without solids

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

High Temperature & Pressure Process Pumps

Operating Range:

| Delivary Size | DN 25 to 250 mm |

| Capacity | upto 1000 m3/hr |

| Head | upto 300m |

| Temperature | upto 450° C |

| Pressure | upto 60 bar |

Design: Centreline – supported rigid foot arrangement, centreline discharge, back pullout design according to API 7th edition. 3 inch discharge and larger are having double volute to minimize radial thrust. Designed with heavy-duty shaft and bearings. Shaft diameter, bearing span and overhung so engineered to give very low deflection. Renewable impeller and casing wear rings.

Application:

- For operations in process industry and transfer systems – refineries, oil and gas fields on/off-shore, gas processing, transport systems, handling of liquid gases, petrochemical industry, chemical industry, energy conservation, and heat carrier systems.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C, and material combination as per API – 610.

Mixed Flow Pumps

Operating Range:

| Delivary Size | DN 200 to 450 mm |

| Capacity | upto 3000 m3/hr |

| Head | upto 40m |

| Temperature | upto 110° C |

| Pressure | upto 7.5 bar |

Design: Horizontal, single stage, volute casing pumps with discharge branch arranged tangentially upwards/horizontal, flanged to a bearing pedestal. The pump is normally provided with open impeller.

Application:

- Pumping of clean, turbid or slightly contaminated liquids against medium and low heads in water works, sewage works, for irrigation and drainage, dewatering, pumping sea water and sugar industry, for spray pond/injection water applications.

- Suitable as coolant pumps in power stations and steel works pumping low concentration cellulose suspensions.

Materials: Graded cast iron, Bronze and CF8M (SS-316)

Paper Stock Pumps

Operating Range:

| Delivary Size | DN 80 to 350 mm |

| Capacity | upto 2250 m3/hr |

| Head | upto 80m |

| Temperature | upto 140° C |

| Pressure | upto 22 bar |

Design: Heavy duty, horizontal, centrifugal, back pull out design, according to DIN 24256. Open impellers are provided with renewable front wear plate and closed impellers with wear-ring. Simple external axial adjustment for impeller wear.

Application:

- Designed for handling paper stocks and pulps upto 7% consistency

- Also suitable for heavily contaminated liquids, raw sewage, roughly screened sewage, fresh, digested and activated sludge from clarification plants, and sludge water from gravel and clay pits, settling tanks

The wide passages in the suction zone of the impeller with less number of vanes and non-clogging design helps to handle stocks easily.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

Paper Stock Pumps

Operating Range:

| Delivary Size | DN 32 to 300 mm |

| Capacity | upto 1800 m3/hr |

| Head | upto 150m |

| Temperature | upto 140° C |

| Pressure | upto 22 bar |

Design: Horizontal, single stage, radial split centrifugal pump with back pull out design. Pumps stock like water resulting in substantial power saving. Wear plate – impeller gap is externally adjustable, hence pump performance and efficiency remain high. Open impellers are specifically designed for stock up 8%. Dynamic seal can handle stock upto 8 % without external sealing water. Mechanical seal/packed stuffing boxes are also available. The prefixed rotor with heavy-duty bearings eliminates seal and bearing problems.

Application:

- Used for continuous operation in process industries, for the pumping of clean, abrasive/corrosive liquids and various stocks up to 8% consistency.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

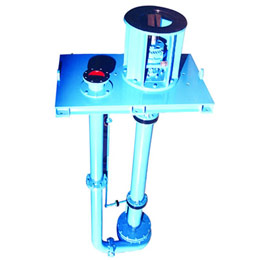

Vertical Cantilever Pumps

Operating Range:

| Delivary Size | DN 25 to 150 mm |

| Capacity | upto 500 m3/hr |

| Head | upto 50m |

| Temperature | upto 150° C |

Design: Vertical suspended pumps with closed and open impellers, for wet pit or dry pit applications, wear resistant design, overhung impellers. Two bearings support are provided above the base plate and intermediate bush bearings are avoided. Suitable for maximum submersion depth over 2 metres. For more depth, suction spool is used. Self-priming, simple mounting.

Application:

- Cantilever design best suits to highly corrosive applications as intermediate bush bearings are avoided.

- Recommended where space economy matters

- Vertical pumps are reliable alternatives to horizontal pumps

- Suitable for clear liquids, acids, alkalis, hydrocarbons, slurries, waste water, sugar melts, detergents etc.

Materials: Graded cast iron /Ni-hard-IV/WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

Vertical Pumps

Operating Range:

| Delivary Size | DN 25 to 300 mm |

| Capacity | upto 900 m3/hr |

| Head | upto 120m |

| Temperature | upto 120° C |

Design: Vertical suspended pumps with closed and open impellers, for wet pit or dry pit applications, wear resistant design, overhung impellers upto 2 metres submersion depth, intermediate bush bearing support for submersion depth over 2 metres. Self-priming, simple mounting.

Application:

- Recommended where space economy matters

- Vertical pumps are reliable alternatives to horizontal pumps

- Suitable for clear liquids, acids, alkalis, hydrocarbons, slurries, waste water, sugar melts, detergents etc.

Materials: Graded cast iron /Ni-hard-IV/WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy – 20/Hastalloy – B/ Hastalloy – C etc.

Water Pumps

Operating Range:

| Delivary Size | DN 32 to 150 mm |

| Capacity | upto 550 m3/hr |

| Head | upto 100m |

| Temperature | upto 160° C |

| Pressure | upto 16 bar |

Design: Horizontal, radial split, volute casing pumps according to DIN 24255 std. with closed impeller, end suction, top centre line discharge. Back pull out design enables to remove the rotor without disturbing the pipelines.

Application:

- For handling clean or slightly turbid non-aggressive liquids.

- Suitable for pumping condensate, general water supply in agriculture, trade, and industries with favourable NPSH condition.

Materials: Cast Iron and Bronze.