Metal Expansion Joint

Metal Expansion Joint

Metallic bellows expansion joints are used in pipelines to absorb the thermal expansion and the effects of it. Quality Products is a customer-oriented metal expansion joint manufacturer in India that produces a wide range of bellow joints as per the specifications required.

Metal expansion joint use bellows to convey high temperature and pressure substances in pipelines and ducts. Since most industries today deal with pipelines carrying materials of high temperature and pressure, thermal expansion is common. This effect can cause mechanical deformation and vibrations which can eventually cause cracks, leakages, and even failure of the entire system. To avoid this from happening,

Metal expansion joint

are used.

EXPANSION JOINTS

AXIAL

AXIAL

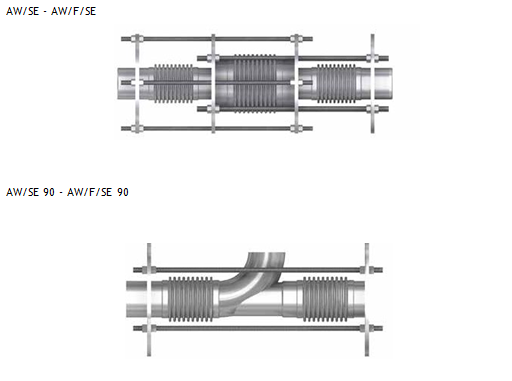

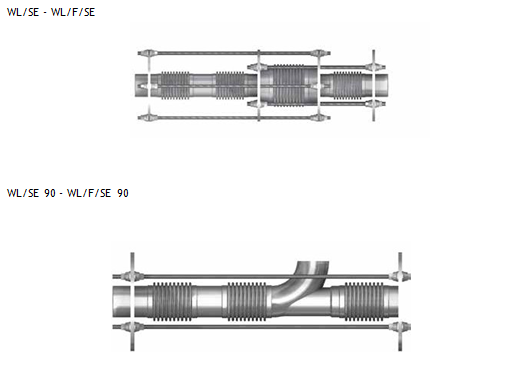

UNIVERSAL

UNIVERSAL

HINGED

HINGED

GIMBAL

GIMBAL

LATERAL

LATERAL

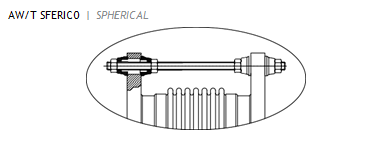

LATERAL SPHERICAL

LATERAL SPHERICAL

PRESSURE BALANCED AXIAL

PRESSURE BALANCED AXIAL

GIMBAL

GIMBAL

BELLOW

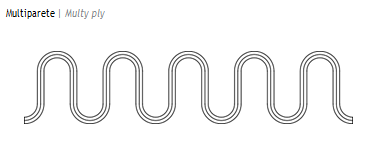

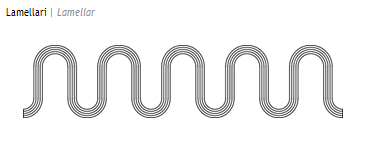

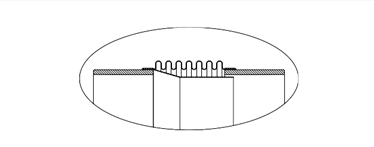

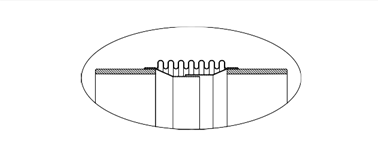

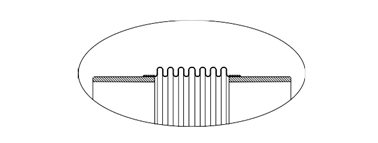

The bellows is the fundamental part of the expansion joint, and it is obtained by hydraulic or mechanic trial from stainless steel or alloy steel having only one longitudinal welding. A controlled behaviour produces a set of parallel metallic waves, that ensure maximum flexibility and reliability.

Our system of calculation furnishes the stress analysis of the bellows, which allows to make calculations according to customer’s specifications.

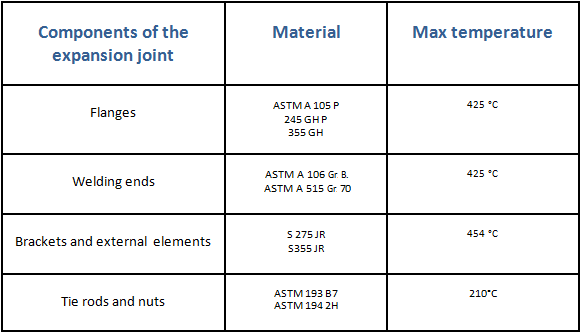

MATERIALS

The basic material to be used for the moulding of the bellows, have to meet the following characteristics:

- efforts resistant

- corrosion resistant

- weld ability

For these reasons, the material more used is the AISI 321 stainless steel (max. temp. 800°C). For superior values of temperature or corrosion it is used AISI 316/316L stainless steel, or alloy steels as Inconel, Incoloy, Hastelloy, Nichel and Monel.

PLANNING AND CONSTRUCTION

Giorgi’s expansion joints are planned and manufactured according to:

- ASME VIII 1 and 2

- EJMA

- RINA

- ISPESEL

- TUV

ACCESSORIES

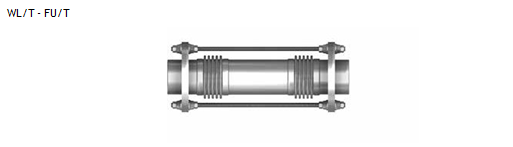

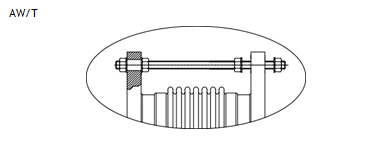

TIERODS

According to the use we can distinguish:

- tierods as run limiting device

- tierods for presetting to the mounting

- tierods to support the thrust due to internal pressure

SLEEVE

To avoid direct contact between bellow and fluid a sleeve is welded on the internal side of the expansion joint. It allows to reduce thermal strains, to reduce loss of head, turbulences and erosion.

TERMINALS

We can produce expansion joints complete of flanges and to be pipe ends. The different terminal are generally produced in carbon steel. On request, it is possible to use stainless steel. Standard flanges are bored according to UNI – ANSI rules, or special and in above mentioned materials.

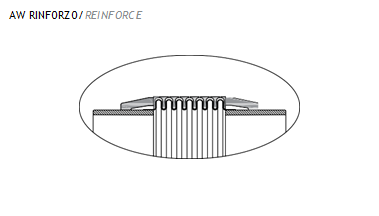

REINFORCING RINGS

When we have to plan a bellow subjected to high pressure it is necessary to use reinforcing rings made of carbon steel sheet. Besides uniformly distributing the compensator, they also act liker unlimiting devices.

EXTERNAL PROTECTION

To protect waves from foreign bodies or to facilitate the application of the insulation, bellow, can externally be wound by a plate, generally in carbon steel.

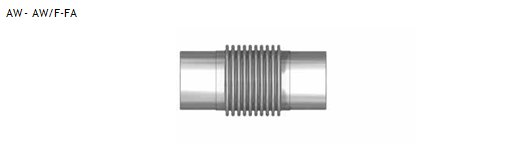

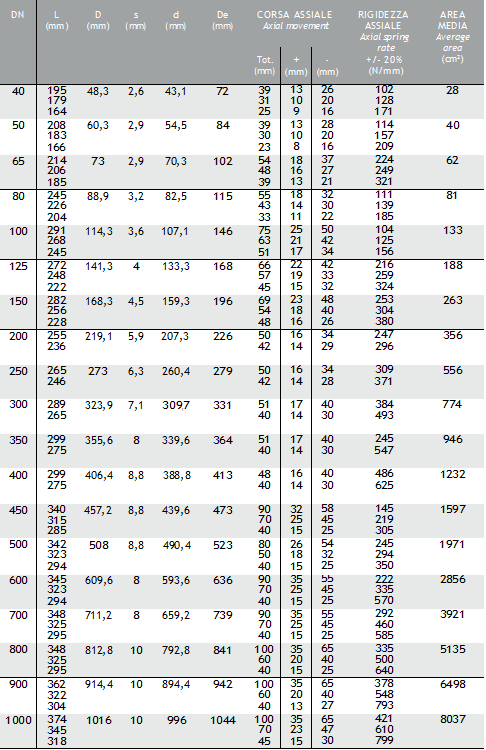

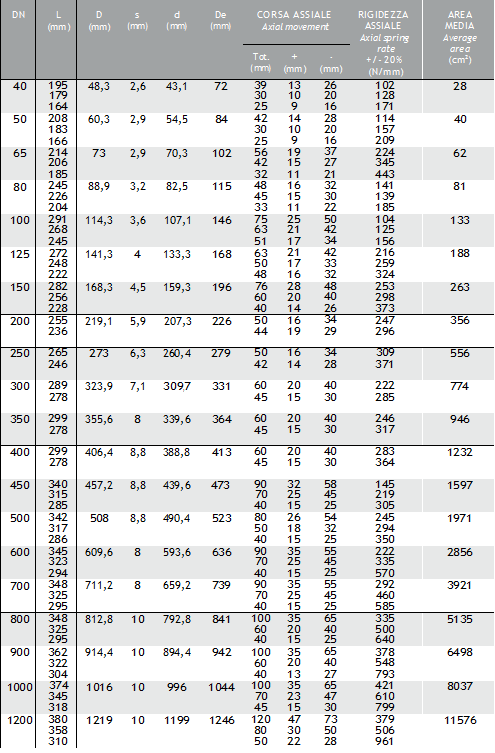

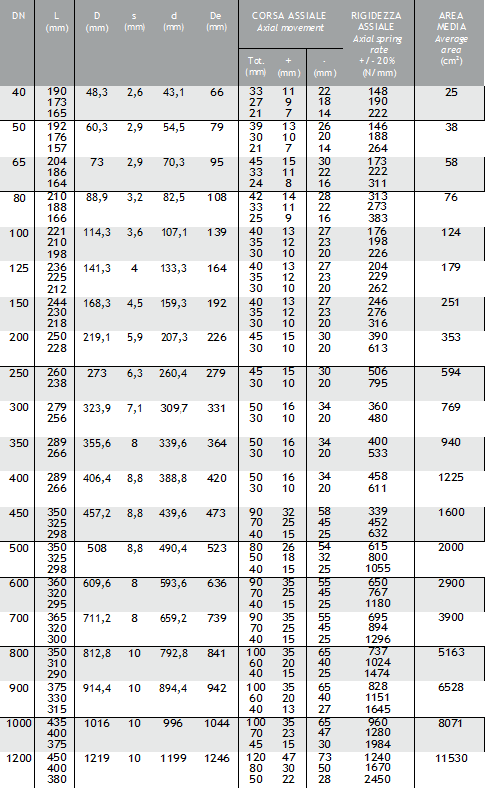

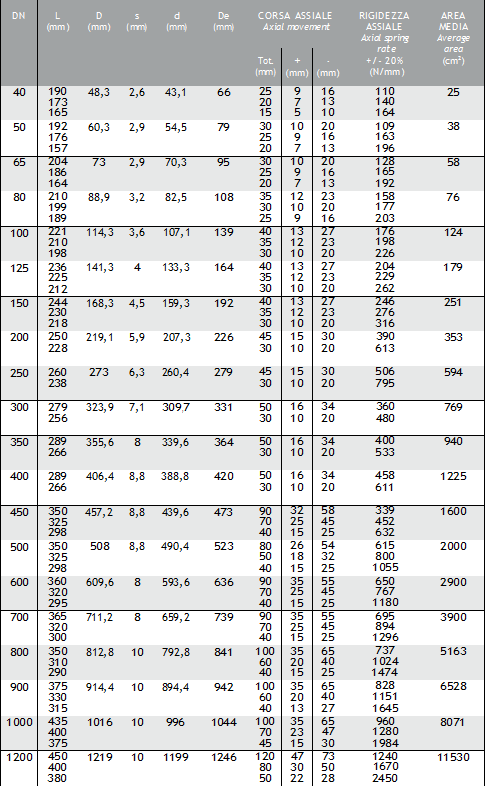

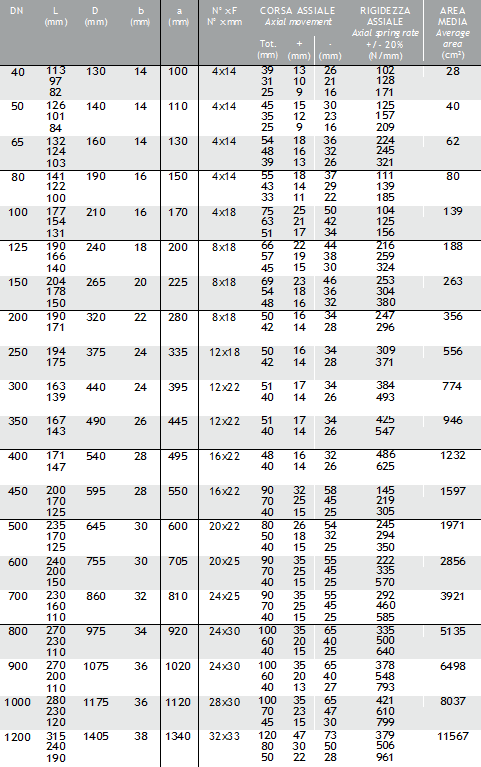

Axial expansion joints with welding ends

Type: AW

PN2,5

Type: AW

PN6

Type: AW

PN10

Type: AW

PN16

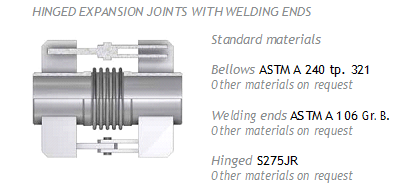

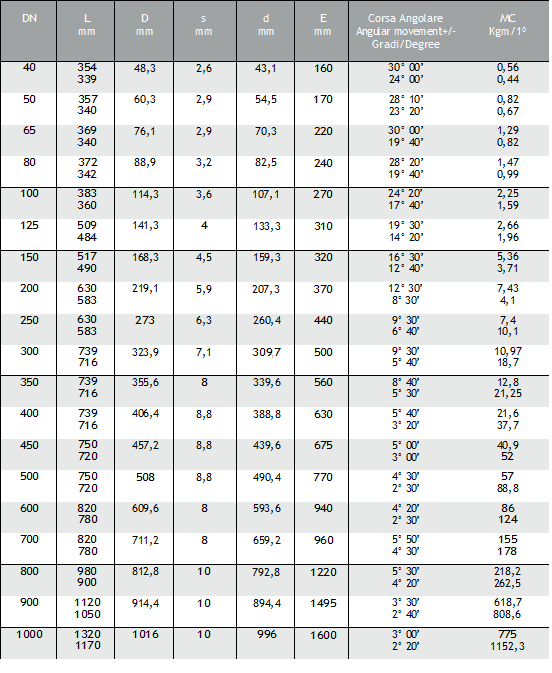

Hinged expansion joints with welding ends

Axial expansion joints with flanged ends

Type: FA

PN2,5

Type: FA

PN6

POPULAR SEARCHES OF METAL EXPANSION JOINT

Metal expansion joint

Metal expansion joint Kuwait

Metal expansion joint in UAE

Metal expansion joint in Kuwait

Metal expansion joint UAE

Metal expansion joint Suppliers

Metal expansion joint Suppliers Kuwait

Metal expansion joint Suppliers in UAE

Metal expansion joint Suppliers in Kuwait