Fabric Expansion Joint

DUCT EXPANSION JOINTS

OVERVIEW: We offer a full range of quality non-metallic “fabric” belt type, and also integrally flanged fully molded type, duct expansion joints for lower pressure gaseous service, including high temperature flue gas.

These expansion joints are used to add flexibility to industrial ducting systems and fan/blower connections to absorb thermal growth, isolate vibration and noise, and allow for misalignments. Their large movements in a given space, small spring rates, and large temperature range give them advantage not available with other types of joints. They are needed in a wide array of industries, including power, petrochemical, pulp &paper, along with countless other industrial facilities. A variety of styles and materials are available to meet the specific requirements of any given application.

The high quality fully molded duct expansion joint types are made from reinforced rubber elastomers,and have the advantage of integral flanges and easy installation. They can be made with or without molded arches, which can provide additional movement and reliability.

The fabric belt joint types combine different steel frame types with elastomers, fluoropolymers, or composite layered materials for complete versatility.

FABRIC BELT EXPANSION JOINTS:

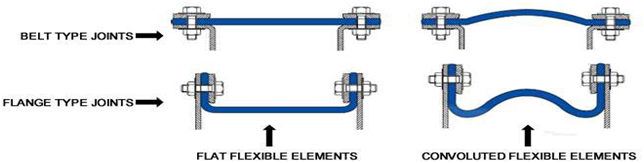

The fabric belt joint types combine different steel frame types and industry proven materials and options. In some instances, additional components such as insulation pillows, accumulation barriers or flow liners are used to help protect the fabric material. The basics are shown below, but a number of other design elements are possible.

The belt type uses a flat belt flexible element made as a flat belt,and is versatile and effective interms of manufacture and installation.And they allow many different types of frames to suit operating conditions. Various baffles (liners) are also commonly used, depending on the service.

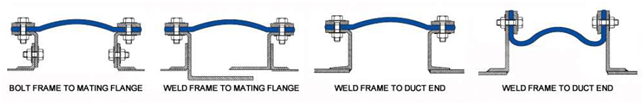

Attachment methods of the frame to the duct include bolt frames to mating flange, weld frames to mating flange, and weld frames to duct end.

Chemical resistance, temperature limitations, abrasion resistance, tensile strength and susceptibility to flutter / vibration are major considerations. When selecting a flexible element fabric material. They are configured either as a flat-type or convex type.

Materials include elastomers, fabrics, insulation materials and fluoro plastics, either constructed in a single layer or multiple layers. See below for the more common material choices, along with allowable movements for various face-to-face widths.

FABRIC BELT EXPANSION JOINT

FLUOROPOLYMER

FABRIC BELT EXPANSION JOINT• COMPOSITE

FULLY MOLDED DUCT EXPANSION JOINT

POPULAR SEARCHES

Duct expansion joints

Duct expansion joints Kuwait

Duct expansion joints in UAE

Duct expansion joint in Kuwait

Duct expansion joint UAE

Fabric belt expansion joint Suppliers

Fabric belt expansion joint Suppliers Kuwait

Fabric belt expansion joint Suppliers in UAE

Fabric belt expansion joint Suppliers in Kuwait